EMI/ ESD Shielding

EMI/ ESD Shielding

EMI or Electromagnetic Interference means disruption of signals of an electronic device due to electromagnetic fields generated by other electronic devices in the surroundings

EMI shielding prevents the signals from being disrupted. The interferences may malfunction a device’s functionality. To avoid this, we use special materials like metals or coatings to absorb or screen out the unwanted disruptions. It is like providing a device with a shield that prevents interference from getting in or out.

Working of EMI shielding

EMI shielding operates on three mechanisms:

- Reflection : Shields made up of metal like copper or aluminum reflect the unwanted signals away from the device.

- Absorption: Some materials absorb the interference and convert the signals into other energy forms like heat.

- Multiple reflections : Multiple reflections are used by layered or thin shields. The signals reflect and weaken before they can become problematic for the device

The overall shielding effect is a sum of Reflection, Absorption, and Internal Reflections.

Factors That Influence Shielding Performance

- Material thickness : Thicker material will block more interference. Thin shields can still be effective if they have a good design.

- Type of Interference : It is easier to block high-frequency signals with metals. Low-frequency magnetic interference needs special materials like mu-metal.

- Design and Coverage : For shielding to work properly, there must be no gaps or empty spaces. Full coverage offers maximum protection

Selecting the correct EMI shielding

For choosing an EMI shielding, first we determine the type and frequency of interference to be blocked. Then, we select materials on the basis of strength, weight, flexibility, and durability to environmental conditions. We make sure to provide full coverage with no gaps or weak points in the shield. We apply multiple or composite materials for increased protection when necessary. Eventually, the end product is tested to guarantee consistent performance and conformity to all standards.

At Luthra Interface Solutions, we offer EMI shielding solutions that aim to guard your products and also satisfy international industry standards.

Frequently Asked Question

- Both types of shielding are important but they work differently and are used for different problems.

- EMI and ESD shielding protect electronic devices in different ways.

EMI shielding blocks high-frequency signals like radio waves or noise coming from devices like motors, phenomenon of lightning, or any other electronics. These signals can cause noise and disturb the working of a device.

ESD shielding protects a device from static electricity. Static electricity can damage sensitive electronic parts.

- A material that protects against EMI may not protect against ESD, and vice versa.

EMI needs thick conductive materials to block fast, changing signals.

ESD needs a material with low surface resistance to stop electric fields. - We can detect EMI using radios but the same cannot be used to detect ESD.

EMI shielding protects electronic devices from unwanted signals. These signals, called electromagnetic interference (EMI), come from motors, mobile phones, lightning, or other nearby electronics. If EMI is not blocked, it can make a device stop working properly, lose data, or show errors. For example, you might hear crackling in a radio or see a screen flicker because of EMI. Shielding helps by blocking or reducing these signals, so the device works smoothly and safely.

- Metals such as Copper, Aluminum and Steel are good for reflecting interference.

- Special alloys like Nickel are best for areas where magnetic shielding is required, especially for low-frequency interference.

- Conductive coatings and paints: Surfaces are coated to provide efficient shielding. Coatings are best for enclosures or products with intricate shapes.

- Foams, fabrics, and films are used in devices which require flexible and lightweight shields. They are used for enclosures and covers.

- Gaskets and seals with metal fillers offer sealing and EMI protection for panel joints, doors, and connectors

Yes, EMI shielding can be customized. Devices differ in shape, size and the amount of protection needed. Considering these factors, various materials like metal foils, coated films, or conductive coatings are used. The material is shaped, cut and designed to match the device perfectly.

- When your device is sensitive to signals like communication systems

- When your device runs along side many other electronic devices and those devices create electric noise.

- When your device is showing errors or making unwanted sounds in the presence of another electronic device.

- Products that communicate wirelessly or through cables need shielding for clear signals

- If your industry requires EMI shielding to follow proper certification or compliance rules.

- When your device is sensitive to signals like communication systems

- When your device runs along side many other electronic devices and those devices create electric noise.

- When your device is showing errors or making unwanted sounds in the presence of another electronic device.

- Products that communicate wirelessly or through cables need shielding for clear signals

- If your industry requires EMI shielding to follow proper certification or compliance rules.

- In electronics like mobile phones, computers, and sound equipment

- In car systems to protect electronic circuits from interference.

- In medical equipment where consistent performance is important.

- In aerospace and defense systems such as satellites, aircraft, and radar equipment.

- Most industries need EMI shielding to pass CE, FCC, ISO, and other regulatory standards.

Specifications

We offer a wide range of EMI shielding materials to suit different performance specifications and budgets. We have flexible materials like conductive fabrics and foams, and highly conductive materials like copper and aluminum foils. Printed conductive inks and coatings are also available for more integrated uses. Each material is selected based on its mechanical strength, thermal stability, shielding effectiveness, and fit with the client's product design.

High levels of signal reduction are provided by our EMI shielding solutions. Our shielding is made to block or contain electromagnetic interference at a wide range of frequencies in high-interference settings like communication devices, automobile systems, or medical equipment.

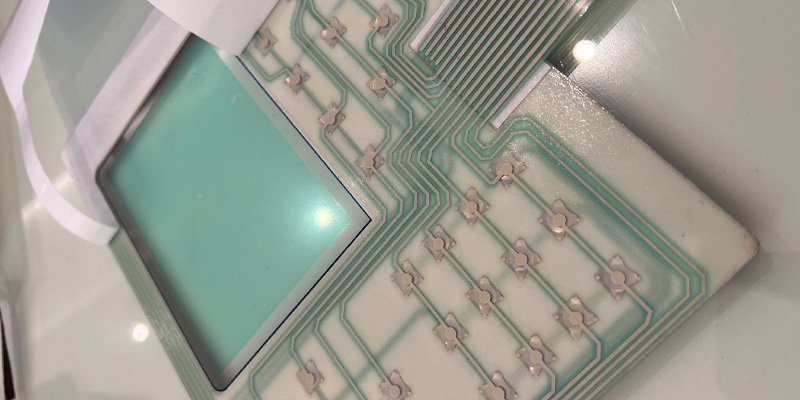

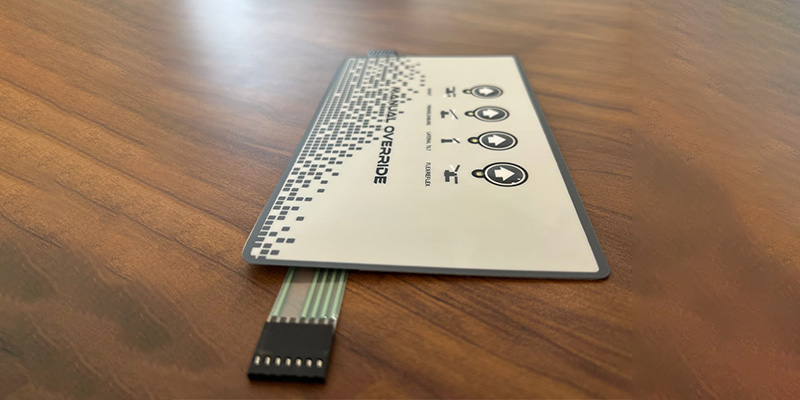

To accommodate the client's application and assembly process, we provide shielding in various forms. It includes tapes, stacked panels, shielding meshes, die-cut gaskets, and printed EMI shielding layers on graphic overlays and membrane switches. Our personnel ensure an accurate fit to the component for optimum EMI performance.

Based on the needs of the application, our shielding products are available with a variety of different adhesive backings. For example, heat-activated adhesives for use in high-temperature applications, non-conductive adhesives for insulating purposes and conductive pressure-sensitive adhesives to maintain the shielding path. We also offer the option of permanent as well as removable adhesives.

We offer our materials in a range of thicknesses from stiff shielding layers to extremely thin films. This allows us to offer high-performance shielding in industrial or automotive environments also, we accommodate the needs of applications like wearables or small electronics. The final thickness is chosen with performance, durability, and integrability in mind.

We accommodate fully customized shapes and designs. With our advanced CNC and laser-cutting technologies, we manufacture shields that exactly duplicate the geometry of your device. Whether you need complex geometries, bends, tabs, slits, or perforations, we can design a shielding component that suits your assembly process and becomes part of your product.

Our shielding products are built to withstand harsh environments. Not only are materials resistant to typical industrial chemicals, dust, moisture, and UV light, but they can also withstand operating temperatures ranging from -40°C to +125°C. This makes them ideal for applications in automotive electronics, defense electronics, outdoor equipment etc.

We utilize materials that meet international safety and environmental regulations. UL-listed shielding parts with flame retardation properties (V-0 rated) and RoHS and REACH-compliant materials are some of the options available. Such certifications ensure that your end product meets industry standards and passes any inspections or audits that may be necessary