Membrane Keypad

Membrane Keypad

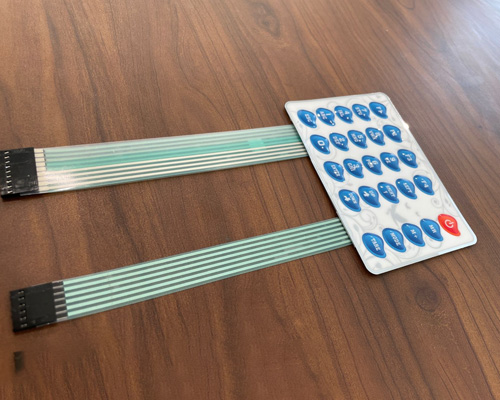

A keypad is an input device or user interface with set of keys, which are arranged in a pad. The face of the keys can have digits, symbols, or alphanumeric letters. A membrane keypad is a keypad with a layer of thin flexible membrane that uses pressure pads with printed circuits to register input.

How it’s made?

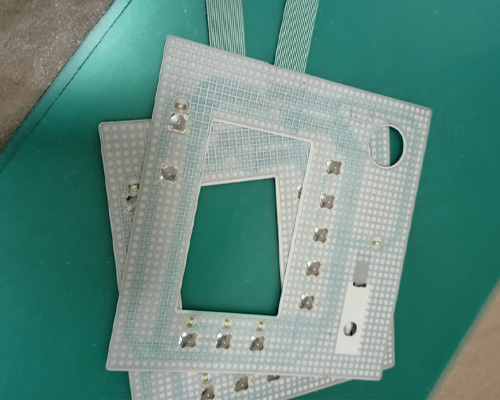

A membrane keypad incorporates many layers in its construction.

The various layers are:

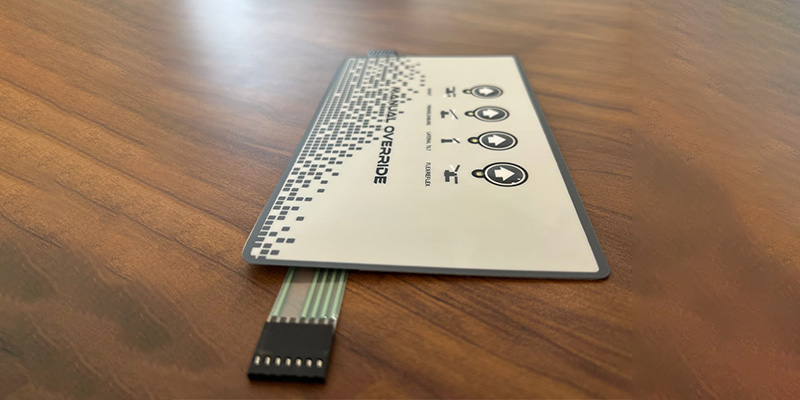

- Overlay : The top-most layer is the membrane made up of polycarbonate (in our case) , it is the interface user interacts with, it is the visual layer, with keys and design.

- Shielding (Optional): Usually preferred for protection of the keypad from electromagnetic interference (EMI) or electrostatic discharge (ESD)—typically in environments with sensitive electronics or high electrical noise.

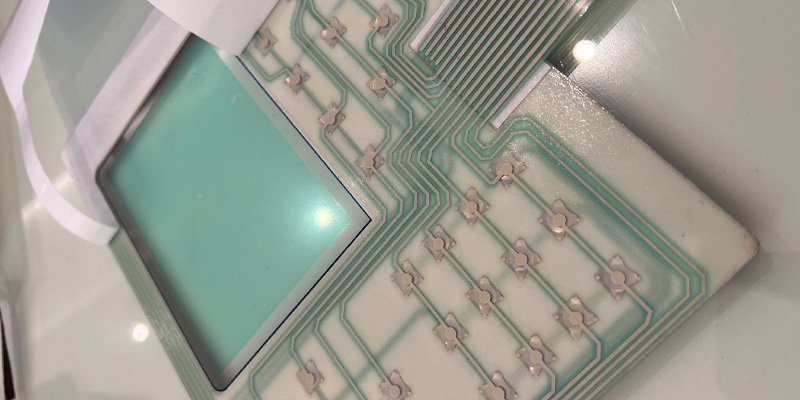

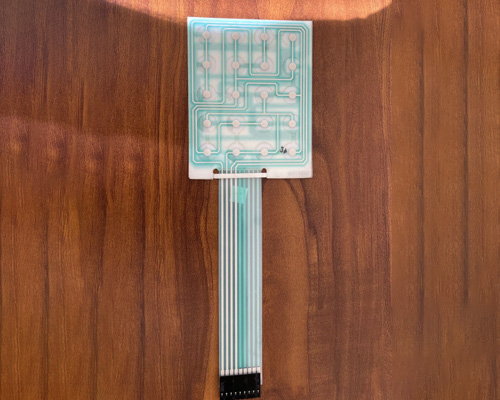

- Top circuit layer or dome The top circuit layer uses conductive ink to create a circuit or instead of a circuit layer, dome switches are placed.

- Spacer : It is like a separating layer between 2 conducting layers. The thickness of a spacer ranges from 0.1mm to 0.10mm and can be increased based on requirements. It keeps the circuits apart to avoid any accidental contact and ensures that feedback is registered only when keys are pressed.

- Bottom circuit layer : It is a printed circuit layer. When keys are pressed, top circuit layer touches bottom circuit layer and circuit completes.

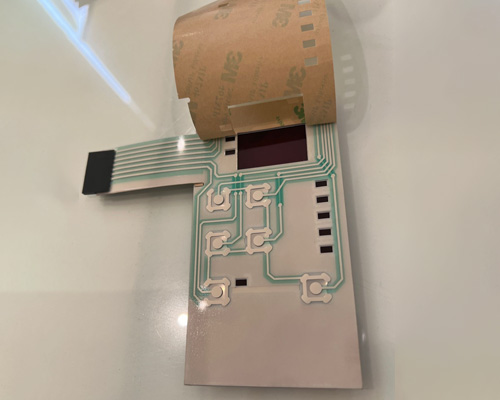

- Adhesive : This is the layer of adhesive to stick the membrane keypad to the machine.

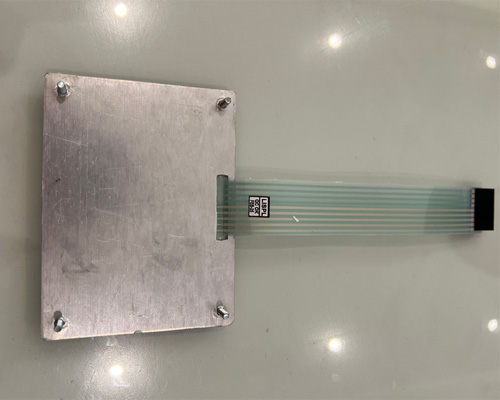

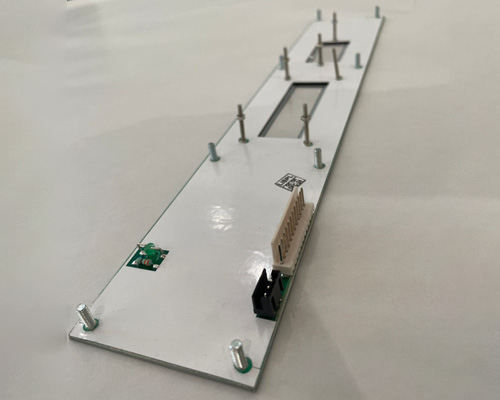

- Backplate (Optional) : It is rigid base made up of metal or plastic, used to mount the membrane keypad assembly. Using a backplate, makes a keypad fixed and prevents it from flexing or bending. It can be incorporated based on requirements.

Frequently Asked Question

A membrane keypad does not have separate keys like a computer keyboard. Instead, it is made up of thin layers. The top most layer is an overlay printed with buttons or keys. Beneath lies a spacer layer which separates the top layer from the bottom layer. The bottom layer is a circuit layer with printed electrical paths. Some keypads also have an extra dome layer for tactile feedback.

When a key is pressed on the top layer, it pushes down through the spacer layer and touches the bottom layer, resulting in an electrical signal. This signal is sent to the device’s controller. Then the device understands which key was pressed and it performs the desired action.

Choose a membrane keypad for your device

- if the interface needs to be flat, strong and easy to use.

- if your device is used in places with dust, water, chemicals like hospitals, kitchens, factories

- If you want the interface to be customized with your logo, colors, and button shapes

- If you want it to be easy to clean and long-lasting.

- If your device needs a compact, flexible interface which can be easily placed on round surfaces.

Other options like touchscreens or mechanical keyboards can be more expensive, harder to clean, and not as durable or suitable for your device. This is why membrane keypads are a smart choice for many machines and devices.

Yes, LEDs and backlighting can be integrated in a membrane keypad

- LEDs are embedded beneath the layers of keypad. They can be placed near the keys or under transparent or translucent areas so that light can pass through. Usually, LEDs are used for illuminating keys or for indicating current status of the device.

- EL backlighting is produced by EL (electroluminescent) sheets. These are thin, flexible light emitting sheets which are placed behind a graphic overlay. They emit a soft, uniform glow which appears to be coming from backside of the keypad. Backlit membrane keypads are commonly used in medical equipment, fitness devices, defense panels etc.

Specifications

We offer both tactile membrane keypad and non-tactile membrane keypad.

On pressing the keys of a tactile membrane keypad, we receive feedback in the form of sound. A membrane keypad is made tactile by adding a tactile dome under each button area.

A non-tactile keypad has flat keys, it does not provide a click feel. When you press a key, it works silently and smoothly, without giving any physical or audible response.

A standard membrane keypad consists of 4 to 6 layers, including the graphic overlay, spacer, top circuit layer, bottom circuit layer, and adhesive layer. Additional layers like an EMI/ESD shielding or rigid backplate can be added based on requirements.

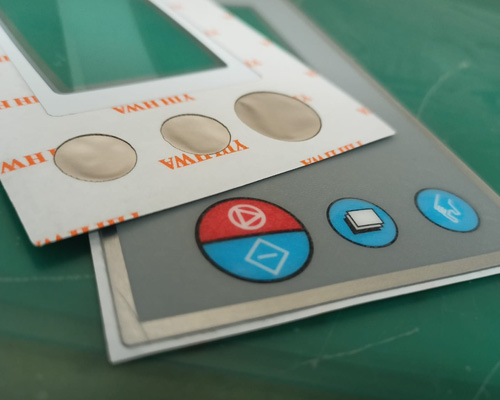

The top layer of the keypad (graphic overlay) can be made using polycarbonate or polyester. Both materials are excellent choices for graphic overlay. The choice of material entirely depends on the respective requirements of the client. Additional finishes like matte, gloss or textured can be provided likewise

We use reverse-side printing on the overlay using screen or digital printing methods. It ensures protection from chemicals, fading and normal wear. Colors are matched accurately using Pantone or RAL standards. This gives the client complete flexibility over their interface design.

We offer dome, pillow, and rim embossing, to raise key areas for better tactile feel. Embossing enhances user guidance by making keys more recognizable to the touch. Also embossing gives a premium look to the design. Height of embossing, key shape and size are entirely customizable.

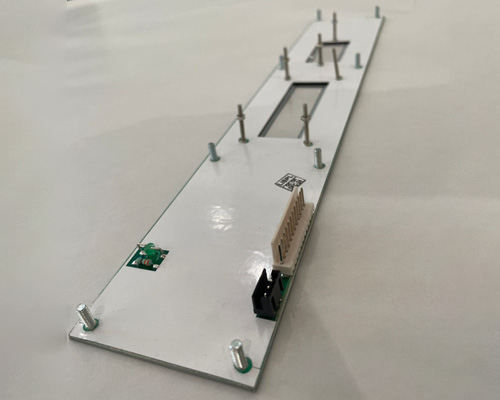

We can integrate backlighting using SMD LEDs, electroluminescent (EL) sheets, light guide films (LGF), or fiber optics. Clients can opt for selective key illumination, full-panel glow, or indicator lighting. These options are especially useful in low-light conditions, night-time use, or for highlighting specific keys

Clients can choose from silver ink printed circuits, flexible copper circuits (FPC), or rigid PCBs, depending on their application. Silver ink circuits are economical and widely used. FPC and PCBs are ideal for more complex or high-density keypads that include components like resistors

We offer IP65, IP67, and IP69-rated membrane keypads that are resistant to dust, moisture, and water.

We use high-performance adhesives from 3M and other equivalent industrial brands that ensure strong, lasting bonds. Adhesives are selected based on surface type, temperature resistance, and application requirements (e.g., indoor vs. outdoor).

Our membrane keypads can be supplied with rear adhesive for peel-and-stick mounting or with screw holes and backplates for mechanical fastening. We also provide aluminum or acrylic baseplates when rigid mounting structure is required.

Our membrane keypads can be supplied with rear adhesive for peel-and-stick mounting or with screw holes and backplates for mechanical fastening. We also provide aluminum or acrylic baseplates when rigid mounting structure is required.

Our membrane keypads can be supplied with rear adhesive for peel-and-stick mounting or with screw holes and backplates for mechanical fastening. We also provide aluminum or acrylic baseplates when rigid mounting structure is required.