Graphic Overlay

Graphic Overlay

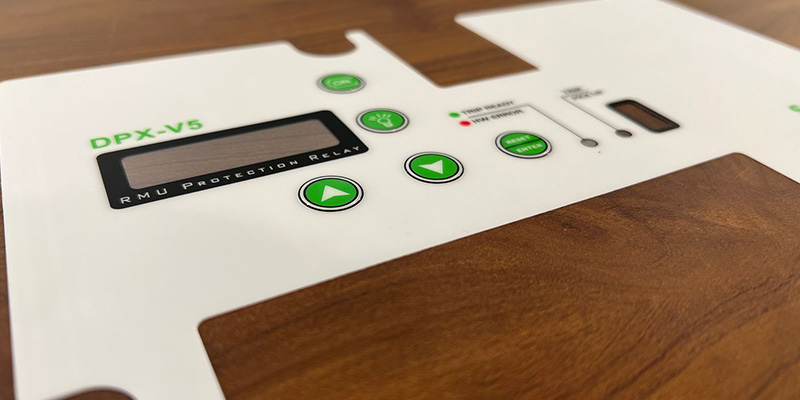

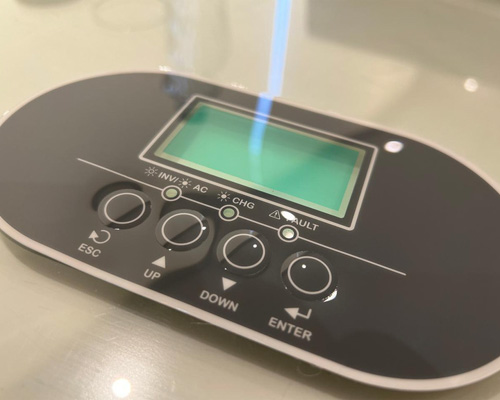

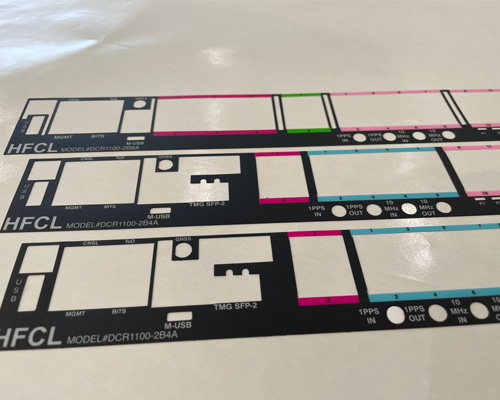

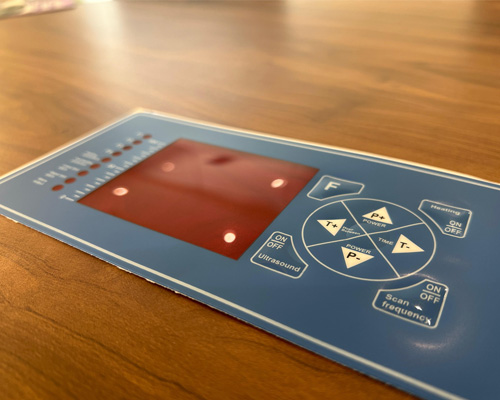

Luthra Interface Solutions manufactures customized graphic overlays, which are durable and of superior quality. Our overlays are reliable and are made to withstand extreme temperatures, exposure to UV light, dirt, dust, chemicals, water and more. A graphic overlay is a printed interface which is used over many devices. It is used for the purpose of identification of the equipment, labelling important information, as an interface between a user and a machine and for protecting the membrane switch underneath. An overlay incorporates many functional elements like keys to operate switches below, window to display electronic information and holes and cut outs to adjust as per machine’s layout. It is a critical layer of user interface which can be made in any shape or size.

Overlays manufactured by Luthra Interface Solutions feature:

- Easy application and usage.

- ROHS certified quality material

- Strong adhesives

- On-time deliveries

There are many points to consider when a graphic overlay is created. At Luthra Interface Solutions, you are advised and consulted about every aspect of the overlay. From initial design to final dispatch, we make sure your requirements are addressed.

Frequently Asked Question

A graphic overlay is a printed layer placed on top of a machine used on various medical devices, control panels, consumer electronics, industrial machinery and more. In short, any machine that needs a reliable, user-friendly, and protective interface layer needs a graphic overlay

- A device will include a graphic overlay in its construction if a user regularly interacts with the device. This means when the device has buttons, switches, or display areas which need to be clearly labeled or protected, then graphic overlays are needed

- Graphic overlays are used when the equipment must show important information like symbols, logos, or instructions on the surface.

- They are also used in those machines in which internal components like membrane switches need shielding from dust, water, chemicals, or scratches.

- Devices that are used frequently, or operate in harsh environments like factories, outdoors and medical industries require overlays because they are durable and long-lasting.

- If a product requires a customized look with specific colors, branding, or shaped cutouts for screens and indicators, then a graphic overlay is essential.

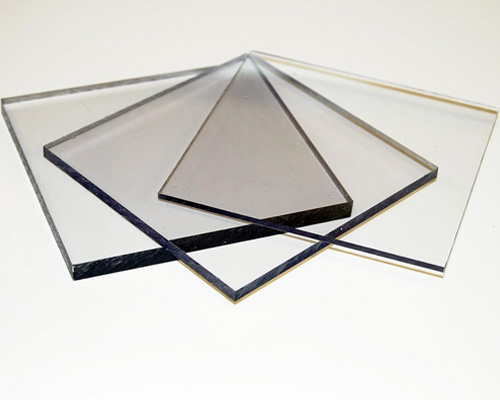

Polycarbonate and polyester are two commonly used materials for manufacturing graphic overlays. Both are durable, printable, flexible materials with good heat resistance, and protection against dust and chemicals.

Polycarbonate provides clarity so it is suitable for overlays requiring high-quality printing and visibility. It is easy to die-cut, emboss, and print on.

Polyester has superior strength, flexibility, and resistance to abrasion and extreme conditions. It performs well in demanding industrial environments.

Both materials are excellent choices with almost same characteristics. The choice solely depends on client’s specific requirements of the device and its operating conditions

Yes, graphic overlays can be fully customized. You can choose any design, logo, text, or color scheme. Even transparent windows, buttons, and cut-outs can be added. Embossing and textures like matte or gloss are also possible.

We make overlays to match your brand and machine perfectly

Yes, because our overlays are made of durable materials so they withstand harsh environmental conditions. They are weatherproof: resistant to water, dirt, sunlight, and chemicals. Additionally, use of UV-resistant ink ensures that the colors on the overlay do not fade, even with long exposure.

A good quality graphic overlay can last for many years. Life span of an overlay depends on material, operating environment and intensity of usage. Even on frequent use, a quality overlay can last for 5 to 10 years or more without major degradation. The durability also depends on proper design, quality of inks, strength of adhesive, and use of protective coatings.

At Luthra Interface Solutions, we use high-quality materials, inks and adhesives to create reliable and long-lasting overlays.

Specifications

Polycarbonate

Acrylic

Vinyl

Polyester

There are diverse materials available in the marketplace. The material is chosen considering many factors like environmental exposure (chemicals, UV, moisture), expected life span, tactile feedback needs, print quality requirements and surface it will be applied to. We, at Luthra Interface Solutions, offer a range of high-quality substrates like polycarbonate, vinyl and acrylic.

Thickness of an overlay is one of the design requirements. Difference in mounting surfaces requires overlays of variable thickness. In case, tactile feedback is required, thicker material is considered as they hold embossed shapes better and give defined and better tactile response.

For industrial machines or outdoor panels operating in rugged environments, thicker overlays are considered. Whereas, thinner overlays are preferred for their flexibility and are ideal for curved or uneven surfaces. If you are not sure about the required thickness, we help you choose the right thickness.

Thickness

Embossing is the process of raising specific areas of the overlay—such as buttons, symbols, or icons. Embossing provides tactile feedback; it makes the keys easily recognizable and adds a raised effect to the design.

At Luthra Interface Solutions, we use embossing based on your product’s design and your requirements, and we follow precise embossing guidelines. You can choose from the different types of embossing we offer

- Pillow Emboss

- Rim Emboss

- Custom Shapes emboss

Entire key area is raised like a soft dome; it is ideal for tactile button areas.

Only the edges of the button are raised, giving it an outline

Logos, icons, or unique areas can be embossed.

Embossing

Colors are an important aspect of overlay. The use of right colors both in quantity and quality increases the appeal of an overlay. At Luthra Interface Solutions, we understand that right color combination strengthens the brand identity.

Using a color depends on how well it aligns with the brand and use of a certain color should make the information readable and clearly visible. It should fit to the functionality of the overlay (like red for stop, green for start). If the product includes backlit icons, displays and windows, color choice should support light transmission, like use of translucent inks for diffusion and same color tinted windows for LEDs.

Some special effects on the overlay requires use of metallic inks and textured inks. We work closely with you to select a color scheme that is visually consistent, functionally effective and long-lasting under use and exposure.

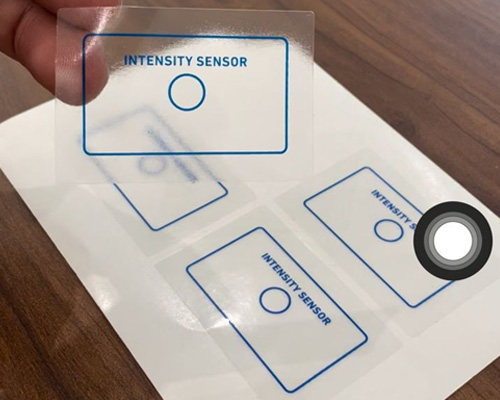

Windows and cut-outs are the small details that are critical to function and fit. We help you define every cut-out — whether it’s for an LED, display, sensor, or button.

Windows are transparent or translucent sections that allow light, displays, or sensors to show through.

Cut-Outs are open areas where the overlay does not cover the underlying surface. Both are custom-shaped and aligned to a product’s design.

- Window options :

- Cut-outs options :

Transparent Windows for screens and displays, offer clear visibility Tinted Windows for LED color or to improve contrast. Dead Front Windows are invisible when off and visible when backlit. Gloss/ Matte finish windows as per client’s requirements.

Cut out for connectors, Speaker and mic cut-outs. Custom slots or shapes cut out based on overlay design. We use laser cutting, CNC, and die-cutting based on the complexity and quantity of the overlay. The alignment of windows and cut-outs is matched precisely with assembly drawings or received cabinets.

We recommend the ideal adhesive solution based on your mounting surface, environmental exposure, and application. A good adhesive ensures that overlay stays in place for longer usage. Our adhesives bond effectively with both the overlay and the mounting surface. Quality adhesives resist environmental stress like heat, moisture, or chemicals. Adhesion is maintained for longer time without peeling, bubbling or shifting.

We select adhesives based on exposure to heat, cold, UV light, moisture, humidity or chemicals. We typically use 3M, Avery Dennison, or equivalent performance-grade adhesives depending on your requirements.

Adhesive

Surface finish affects appearance of an overlay and also affects readability and tactile experience. The finish determines the clarity of printed graphics and how the overlay feels to touch. Different finish types we offer are gloss/ matte/ texture finish/ patterned finish/ brushed finish.

- Gloss finish is clear and has smooth texture.

- Matte Finish is non-reflective and diffuses light. It provides scratch resistance in frequent-touch areas, is anti-glare in bright or outdoor settings and is easy to clean. Texture Finish hides fingerprints and wear marks. It is suitable for harsh or dirty environments

- Brushed/Patterned Finish is used more often for decorative and aesthetics purpose. We also advise combining multiple finishes on one overlay if needed — for example, a gloss window with a matte background.