PU Dome Stickers

PU Dome Stickers

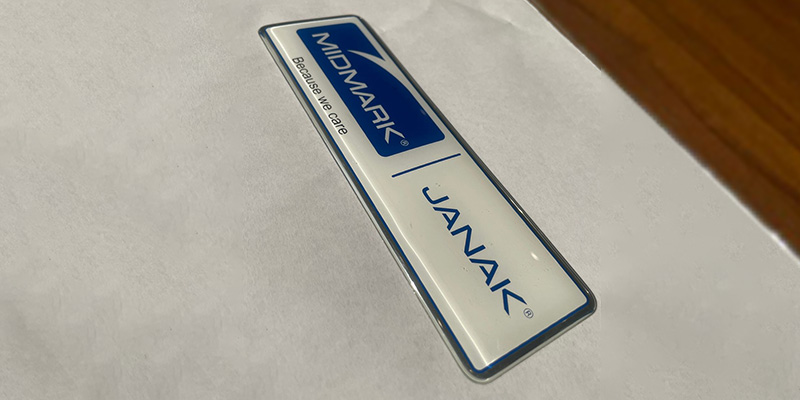

PU dome stickers are printed stickers on top of which polyurethane dome is layered and placed permanently. These stickers are noticeable because of their 3 D appearance.

Properties/ Characteristics of dome labels

- Everlasting : The labels are durable because of the use of quality inks and standard base material. The labels do no lose color and are resistant to scratches and bumps. Due to the use of polyurethane dome, the sticker does not harden or turn yellow over the years.

- Resistant to extreme conditions : The stickers are suitable for use indoors and outdoors and can withstand extreme hot, cold or dry environment. They do not fade in case of prolonged exposure to UV light. They are resistant to water, oil, germ, chemical and what not.

- Strong adhesives : The labels stick firmly on all the surfaces which are suitable for labels.

- Attractive : They are appealing and visually give a premium look. The glossy finish and the 3 D look are the captivating factors.

We at Luthra Interface Solutions offer

- Unquestionable quality

- Durability that exceeds expectations

- Strong adhesion on surfaces suitable for labels

- Compliance requirements like ROHS

- Experienced suppliers, as we have been producing dome stickers for almost 2 decades.

- Delivery as per your requirements, so that your business runs smoothly without delays.

- Pricing suited to your order volumes and needs.

Frequently Asked Question

Dome stickers are perfect for printing company logos and brand images. They are visually appealing and they promote your brand image clearly and for longer time even in the most extreme environments.

First, the base material is decided. Several factors like costs, thickness, surface and application area and adhesion/ durability requirements are to be considered before choosing the base material. PVC, PC, PET are some common base materials for dome stickers.

Next, the design is printed on the material, followed by pouring a mixture of clear liquid polyurethane on top of the printed label. It is left to set for a few hours and eventually it crystallizes into a transparent and glassy 3d sticker.

Epoxy stickers look like PU dome stickers, but their features are contrasting

| Basis of difference | Epoxy stickers | PU Dome stickers |

| Doming material | Epoxy stickers use epoxy resin for doming, which is a | In PU dome stickers, PU resin is used for doming, it is a liquid |

| John | thermosetting polymer, that becomes solid when mixed with a hardener. It starts as a liquid and after curing it turns into a tough glossy material. | polymer that cures into a flexible durable and transparent material |

| Flexibility | Low, as it becomes hard and brittle over the years. It is rigid and more like plastic | High, as it remains soft and bendable after curing. It is comparatively very elastic. |

| Application | Not suitable for long term and outdoor application | Can be used in any environmental setting for many years. |

| UV resistance | These stickers have poor resistance and degrade over prolonged exposure to UV light. They tend to lose shine and become dull and hazy. | They are highly resistant to UV light and maintain high gloss finish even in sunlight. |

| Yellowing | UV exposure, oxidation and age causes yellowing or shrinking. It may fade or turn yellowish indoors within a year. It loses its clarity and brightness with time. | Does not fade or turn yellow because it is extremely resistant to UV rays and oxidation. It is highly stable and looks new for years. |

| Cost | Epoxy resin generally costs less upfront than PU resin, making it the cheaper option initially. It is chosen for short-term usage. | PU resin’s price is higher due to its advanced formulation and superior properties. Despite the higher initial cost, many choose PU resin for its better performance and long-term benefits. |

Yes, dome stickers can be applied to curved surfaces, but with some considerations. The base layer of a dome sticker can be flexible but the dome layer is semi-rigid. This means a dome sticker is best suited only for flat or gently curved surfaces. Dome stickers cannot be applied to tightly curved or irregular surfaces as they might peel, crack or distort over time.

High-quality PU dome stickers are resistant to yellowing and fading, because they are made with UV-stable polyurethane resins. The UV resistant property of PU resin gives the sticker a clear and glossy look even after prolonged exposure to sunlight and environmental conditions. However, poor quality dome stickers may show signs of yellowing over time, when constantly exposed to UV light.

Specifications

We have a lot of different base materials to choose from, so you can find the right one for your product's look and use. Listing all the materials is practically impossible. We consider and advice each base material based on client’s requirements.

We use high-resolution printing to make full-color gradients on our PU dome stickers. We use screen, digital and UV printing to make colors bright and last a long time. We use front printing on materials like vinyl and reverse-printing techniques on material with clear base.

We use high quality UV stable polyurethane resin on our stickers which is more durable and long lasting than epoxy resin. Use of PU results in a clear dome which is resistant to hardening, cracking, fading and yellowing.

We can make a dome sticker in any size or shape you need. Dome stickers are cut to exact sizes, and you can choose from a variety of shapes, including complex shapes like one with inner cutouts, sharp corners, or soft, rounded edges. We can make a sticker that fits perfectly to your requirements

High-performance adhesives that work on a variety of surfaces support our stickers. For demanding applications, you can use industrial-grade adhesives like 3M, or you can use regular acrylic adhesives for everyday use. In situations where temporary placement is necessary, we also provide adhesive options that are detachable and repositionable. All adhesives are made to adhere well to smooth surfaces, such as coated wood, glass, plastic, and metal.

The thickness of a dome sticker can be customized based on design and surface compatibility.

The natural glossy, glass-like finish of PU dome stickers adds depth to color and creates a high-end appearance. For brand alignment or particular design needs, additional surface effects can be added.

The stickers are made to survive harsh environments. The dome layer is weatherproof, waterproof, and resistant to scratches. It is appropriate for both indoor and outdoor applications because it is resistant to mild chemicals, UV radiation, and normal wear and tear. Over time, the dome also repairs itself from small surface dings, maintaining the sticker's brand-new appearance.

Dome stickers work best on surfaces that are flat or gently curved. They can stick to metal, plastic, glass, and other non-porous surfaces when right combination of base material and adhesive are used. We provide advice on material selection for different types of surfaces to guarantee long-term performance.

Dome stickers can have useful components like barcodes, serial numbers, or QR codes, apart from the usual company logo branding. They can be used as tamper-evident labels, promotional badges, or product identifiers. Everywhere they are used, their 3D effect increases brand visibility and offers a high perceived value.